ZINGA on Transmission Towers

The lifetime of a transmission tower may reach 80 to 120 years, proper maintenance provided. Within this time some elements need to be changed (maybe earth wires, conductors, clamps), others need refurbishment (foundations, earthing grid).

In most cases steel towers need protection against corrosion. Hot dip galvanising is a common method for such protection. The galvanising materials do not last forever and after a certain period of time, coating of structures on site becomes necessary (maintenance coating).

ZINGA is the ideal solution when it comes to the protection of pylons or electricity poles. The vast majority of pylons are hot-dipped. This is because they consist of small elements bolted together (easy to hot-dip) and because most pylons are situated in highly corrosive areas.

Since the structures are to be in constant operation modus (a shutdown means no electricity), they can not be dismantled for re-galvanising. Therefore, to ensure cathodic protection, treatment with a galvanic coating is necessary. ZINGA can recharge the galvanic protection!

Case Study

Industry

Power

Client

Transgrid

Asset

Transmission Towers

Summary

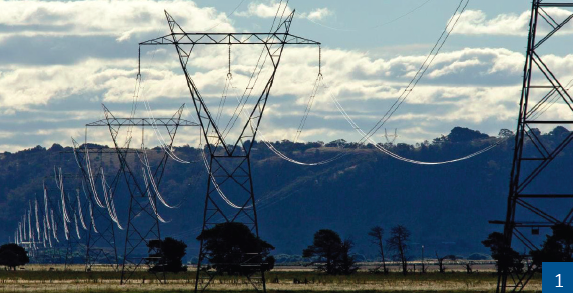

Transgrid operates the majority of the electricity grid in New South Wales and is responsible for maintaining the assets.

There are approximately 20,000 steel lattice tower structures in the state that Transgrid utilises to distribute electricity around the state.

Transgrid has specified Zinga since 2007 to protect their towers against corrosion and to date have had various application contractors apply Zinga to 300 of their towers.

The photo (2) shows a project completed in 2014 in the Munmorah region. The specification called for two coats of Zinga each at 60μm dry film thickness and was executed successfully by NJ Construction. In 2019 a ZINGA team revisited the site, the inspection showed the coating to be performing exactly as expected with no appreciable DFT loss.

Transgrid continues to specify the Zinga product for all their tower coating works.

Transgrid is responsible for maintaining approximately 20,000 transmission towers across NSW.

Munmorah tower completed in 2014 demonstrating no corrosion or coating loss after 5 years.