ZINGA on Bridges

The primary cause of corrosion on steel bridges is the exposure of the steel to atmospheric conditions. This corrosion is greatly accelerated by marine (salt spray) exposures and industrial environments. Since bridges cannot be dismantled, they should be protected by protective coatings or paints.

Changes in environmental protection regulations have brought about a transformation of the approach to corrosion protection for steel bridges. Until the mid to late 1970s, virtually all steel bridges were protected from corrosion by multiple thin coats of lead and chromate-containing alkyd paints applied directly over mill scale on the formed steel. Maintenance painting for prevention of corrosion was rare and was primarily practised on larger bridge structures.

Indirect costs to the public are estimated to be at least 10 times higher than the direct corrosion costs: construction of new bridges, failure, or maintenance of corroded bridges can increase wear and tear on automobiles, gasoline usage, and delays in transportation due to bridge closures and, above all, structurally deficient bridges cause a risk to public safety.

ZINGA offers an environmentally friendly, sustainable and effective solution for the corrosion protection of steel bridges, especially in severe marine corrosive environments.

Case Study

Industry

Bridge Infrastructure

Client

Queensland Rail

Asset

Rathdowney Rail Bridges

Summary

There are a number of steel bridges on the Standard Gauge line running from Sydney to Brisbane through the Rathdowney region ranging from 1 to 6 spans. These bridges would have been built around the 1930’s. In 2003 QR allocated a set budget to blast and repaint as many of the bridges in the region as possible with 2 coats of Zinga to a DFT of between 120 and 150 microns. It was initially expected (based on historic costs of existing systems) that they would paint 6 or 7 bridges, however the project team completed a total of 11 bridges within the allocated budget, due to the speed with which Zinga can be applied in comparison to conventional coatings. After 10 years of service, the coating is in excellent condition.

Typical corrosion of the bridge before maintenance.

Zinga’s performance was exceptional after 10 years.

The coating had lost no film thickness after 10 years.

Case Study

Industry

Bridge Infrastructure

Client

TMR and Queensland Rail

Asset

Bridges

Summary

The Burdekin River Bridge or “Silverlink” as it is known to the locals, is an extremely important piece of infrastructure in Northern Queensland. Without this structure motorists would face an extra four hours travel time on their journey in that part of the state.

While ZINGA has been used for patch repair on the bridge since 2005, TMR and Queensland Rail chose to apply ZINGA and Alu ZM to the bridge’s 22 approach spans of the iconic bridge in 2010 due to it’s durability, ease of application and silver finish.

The coatings were applied to the road and rail approaches by in-house Queensland Rail teams to an original specification of 120μm. A further 40 micron DFT was applied over the Zinga on the rail approach only.

In early 2013, the road support structures were also coated with ZINGA, beginning with a class Sa 21⁄2 abrasive blast clean, followed by 2 coats of ZINGA to an average dry film thickness of 180 μm.

As the coating system for the rail support structure required a decorative silver finish, and the coating system was therefore as described but incorporated a coat of ALU ZM. A dry film thickness of 40 μm was specified.

In 2019 the ZINGA team conducted an inspection during which dry film thickness readings were taken and revealed no appreciable film thickness loss in nine years.

After nine years, there is no corrosion and no loss of coating thickness.

The bridge was painted in 2010 by Queensland Rail teams.

Before ALU ZM application

After ALU ZM application

Case Study

Industry

Bridge Infrastructure

Client

VicRoads

Asset

Molisson Street Bridge

Summary

The Molisson Street Bridge in Kyneton, Victoria, Australia and has served the past 100 years for traffic over the Compaspe River and was the first of many bridges to be protected with ZINGA after it was rapidly deteriorating due to corrosion.

As the previous coating system was lead-based and so badly corroded, the old coating had to be removed completely and the bridge had to be fully encapsulated.

The ZINGA Coating system used on the bridge will provide exceptional long term protection for what is a National Heritage structure, including excellent UV resistance and weathering properties. ZINGA’s 96% pure zinc content is expected to extend the service life of the bridge by 30 years. The coating will also not become brittle as the bridge flexes over time, thus preventing possible coating failures.

Before Zinga application. Note the increased beam corrosion.

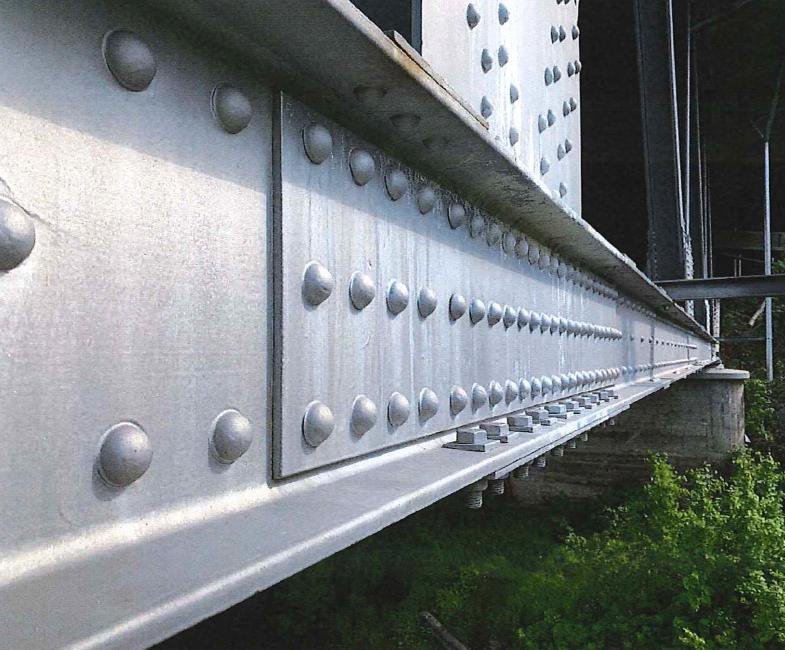

After Zinga application. All rivets, edges and bolts were stripe coated.

After Zinga application

Case Study

Industry

Bridge Infrastructure

Client

Queensland Rail

Asset

Bremer River Bridge

Summary

The Bremer River Rail Bridge spans theBremer River between the towns of Ipswich and North Ipswich,Queensland, Australia. The Bridge was completed at the beginning of the 20th century and has a length of 380 meters.

Two 60 µm DFT coats of Zinga was applied to the bridge in late 2011, early 2012.

In December 2023, 11 years after the original application, a representative of ZINGA Australia and of ZINGAMETALL Belgium went on site to conduct a condition survey on the ZINGA unique system. The anticorrosion protection of the bridge is still in perfect condition.

Case Study

Industry

Bridge Infrastructure

Client

Queensland Road

Asset

Sadliers Crossing Railway Bridge

Summary

Constructed in 1902, the Sadliers Crossing Railway Bridge is a National Heritage listed railway bridge over the Bremer River in Ipswich. The two span Whipple truss bridge has continuous rolled steel joists and is 45.7m in length, making it the second longest span if its type in Queensland.

The bridge was heavily corroded and in poor condition when Zinga Australia proposed to refurbish it with Zinga for sustainable, long-term protection.

In December 2023, 14 years after the original application, a representative of ZINGA Australia and of ZINGAMETALL Belgium went on site to conduct a condition survey. After a light wash with water, the bridge surface revealed a perfect ZINGANIZED finish, meaning the bridge was still fully protected from corrosion.

The bridge was in a bad state of repair prior to refurbishment.

Before Zinga treatment.

After refurbishment.

The ZINGA coating remained in good condition when inspected 14 years.

Case Study

Industry

Bridge Infrastructure

Asset

Reynella Bridge

Summary

The Reynella Bridge south of Adelaide in South Australia had suffered from a high degree of corrosion prior to its refurbishment in 2008. ZINGA was first applied as primer at 60 µm DFT. This was followed by one 80 µm DFT coat of Monoprimer and finished with one 80 µm DFT coat of Alufer WR.

This image shows the severity of the corrosion prior to the Zinga refurbishment.

The beams under the bridge after the restoration.

Case Study

Industry

Bridge Infrastructure

Client

Viken Flykeskommune Authorities

Asset

Bjørnetangen Bridge

Summary

Spanning 72 metres across the Snarumselva River in Norway, the Bjørnetangen Bridge is the first of seven bridges to be repaired with Zinga in the country’s Vuken Fylkes Kommune. As shown in the images below, the previous coating system (zinc rich primer + topcoat) had failed at quite an early stage, hence the need for refurbishment.

During the summer of 2021, it was decided that the bridge should be repaired with a ZINGA stand-alone system of 2 x 60 µm DFT, which they ordered to ZINGA AS, the Norwegian ZINGA Distributor.

Zinga was applied in two 60 μm DFT coats, resulting in a total coverage of 120 μm DFT. The total repaired surface was 930 m² and a pull-off test performed seven days after application found the new Zinga system to be 9.46 MPa.

Case Study

Industry

Bridge Infrastructure

Client

Cardiff Harbour Authority

Asset

Cardiff Harbour Water Taxi Berth

Summary

When a new water taxi berth was constructed on the River Taff for the Cardiff Harbour Authority, the contractors selected ZINGA as the anti-corrosion system of choice due to its superior finish, cost effectiveness and the fact that its application didn’t limit the size of the structure. It also meant that the project could be completed in less time.

Case Study

Industry

Bridge Infrastructure

Client

Norwegian Ministry of Roads (SVV)

Asset

Bommestad Bridge

Summary

The Bommestad bridge located on the E-18 in Vestfold, Larvik, Norway, was refurbished with ZINGA from 2000 till 2001. The Norwegian Ministry of Roads selected ZINGA as the protective primer as it was far more cost effective and practical than thermally sprayed zinc.

On 6 June 2019, more than 18 years after the original coating works, a third-party condition survey was conducted by Safe Control in the presence of the Managing Director of ZINGA Norway and 2 engineer-inspectors of SVV.

In his conclusions, the Safe Control inspector Mr. G-E. Kile stated:

“In my opinion, the protection was good as it was applied in 2000/2001. As far as I know, it was estimated a life time of 20 years, which has been fulfilled.”